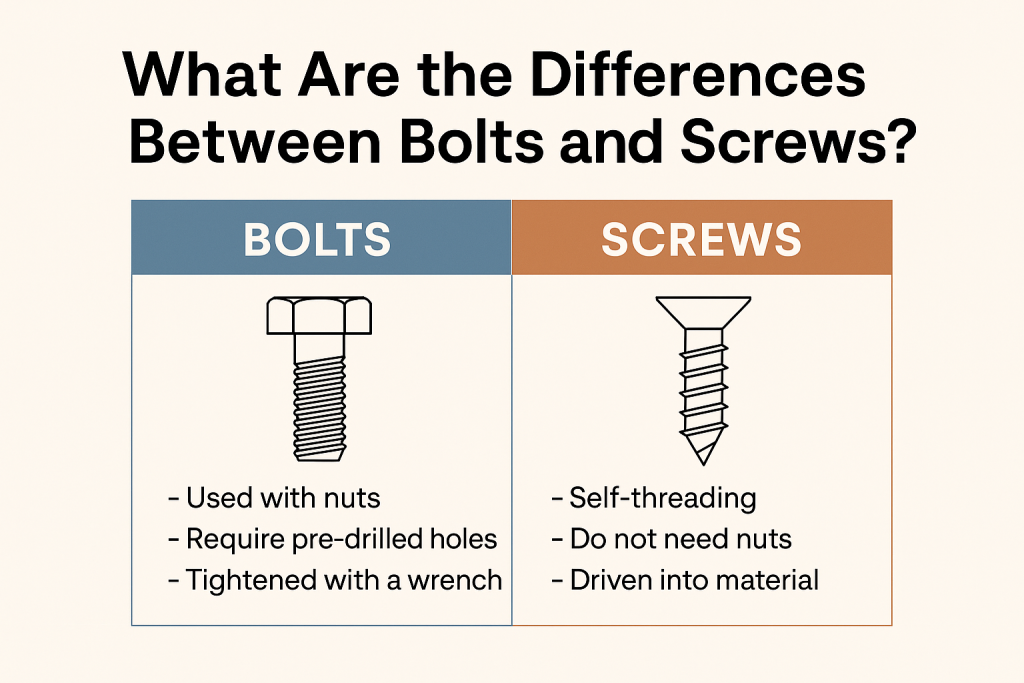

Fasteners like bolts and screws are essential in construction, machinery, furniture, and countless other applications. While many people use the terms interchangeably, bolts and screws are not the same. Their design, function, and best-use scenarios differ significantly.

Understanding these differences is key for ensuring efficiency, strength, and durability in any assembly. Bolts are typically paired with nuts for heavy-duty purposes, while screws create their own threads and are better suited for lighter, versatile tasks.

Choosing the right fastener can make all the difference in the reliability of your project. This guide breaks down the key distinctions, applications, installation methods, and advantages of bolts and screws to help you make informed choices.

How Do Bolts and Screws Differ in Design?

The design of each fastener directly influences how it functions. Let’s look at the defining features of bolts and screws.

Bolts: Main Characteristics

-

Externally threaded and usually paired with nuts to create strong clamping force.

-

Require pre-drilled or pre-tapped holes for proper installation.

-

Installed using external tools such as wrenches or sockets.

Bolts are built for strength and durability, making them indispensable in construction, machinery, and automotive work.

Common types include:

-

Hex Head Bolts – Highly versatile and strong.

-

Carriage Bolts – Rounded head with square neck to prevent turning.

-

Eye Bolts – Designed for lifting and heavy load-bearing.

Screws: Main Characteristics

-

Self-threading fasteners that cut into material as they’re driven in.

-

Often don’t require nuts or pre-drilled holes.

-

Installed easily using a screwdriver or drill.

Screws are widely used for lighter-duty projects like woodworking, electronics, and home repairs.

Common types include:

-

Flat-Head Screws – Sit flush with the surface.

-

Round-Head Screws – Decorative while offering a secure grip.

-

Machine Screws – Used in tapped holes or with threaded inserts.

Applications: When to Use Bolts vs. Screws

Best Uses for Bolts

Bolts shine in projects where high strength and structural integrity are required:

-

Construction – Frameworks, bridges, and structural assemblies.

-

Heavy Machinery – Securing large, moving, or vibrating parts.

-

Automotive & Aerospace – Critical joints in vehicles, airplanes, and equipment.

Bolts are often combined with nuts and washers, which spread the load evenly and reduce the risk of material damage.

Best Uses for Screws

Screws are better for lighter, everyday, or precise applications:

-

Woodworking – Furniture, cabinetry, and wooden structures.

-

DIY & Repairs – Mounting shelves, fixtures, and hardware.

-

Electronics – Small screws in delicate devices like laptops and phones.

Because screws are simple to install and remove, they’re excellent for projects requiring quick assembly and flexibility.

Installation: How They Differ

Installing Bolts

-

Align and prepare pre-drilled or tapped holes.

-

Insert the bolt through the holes.

-

Add washer and nut (if needed).

-

Tighten with a wrench or socket, following torque guidelines.

This method produces strong, vibration-resistant joints ideal for high-stress environments.

Installing Screws

-

Align screw with the surface or pre-drilled pilot hole.

-

Drive in with screwdriver or drill.

-

Stop when the head is flush or at the required depth.

The process is faster and simpler than bolts, making screws more user-friendly.

Advantages of Bolts Over Screws

While both are important, bolts provide benefits that screws cannot always match:

-

Superior Strength – Bolts paired with nuts can withstand heavy loads.

-

Reusability – Bolts can be removed and reused multiple times without losing integrity.

-

Vibration Resistance – Nuts, bolts, and washers create stable joints even in dynamic environments.

-

Customization – Available in countless sizes, materials, and head types.

-

Reliability in Critical Applications – Bolts are trusted for bridges, engines, and machinery where failure is not an option.

The Role of Materials

The choice of material greatly affects performance and durability:

-

Steel – Strong and affordable, but requires protective coatings against rust.

-

Stainless Steel – Excellent corrosion resistance for outdoor, marine, or chemical use.

-

Aluminum – Lightweight and corrosion-resistant, common in aerospace and electronics.

-

Brass – Decorative, corrosion-resistant, and non-magnetic, often used in plumbing or electronics.

Why it matters: Using the wrong material (e.g., plain steel in a marine environment) can lead to premature failure, corrosion, or safety risks.

Best Practices for Using Bolts and Screws

For Bolts:

-

Use washers to distribute loads.

-

Choose the correct length to ensure secure threading.

-

Apply thread-locking compounds in vibration-heavy environments.

-

Always follow torque specifications to avoid under- or over-tightening.

For Screws:

-

Pre-drill holes in hard materials to prevent splitting.

-

Avoid over-tightening, which can strip threads.

-

Match screw type and length to the application for maximum strength.

Conclusion

Bolts and screws are both crucial fasteners, but their roles differ:

-

Bolts: Heavy-duty, reusable, stable under vibration, and reliable for structural applications.

-

Screws: Convenient, versatile, and perfect for lighter or precision-based projects.

By understanding their differences in design, application, installation, and material selection, you can ensure safe, long-lasting, and efficient assemblies.

When precision and quality matter most, KingsMG provides expert CNC solutions tailored to your fastening needs. From guidance in choosing the right fasteners to advanced machining and installation support, KingsMG ensures your projects meet the highest standards of performance and durability.

Discover more about their advanced CNC services and explore how KingsMG can support your next project with expertise and reliability.