Design for Manufacturing (DFM) Guide

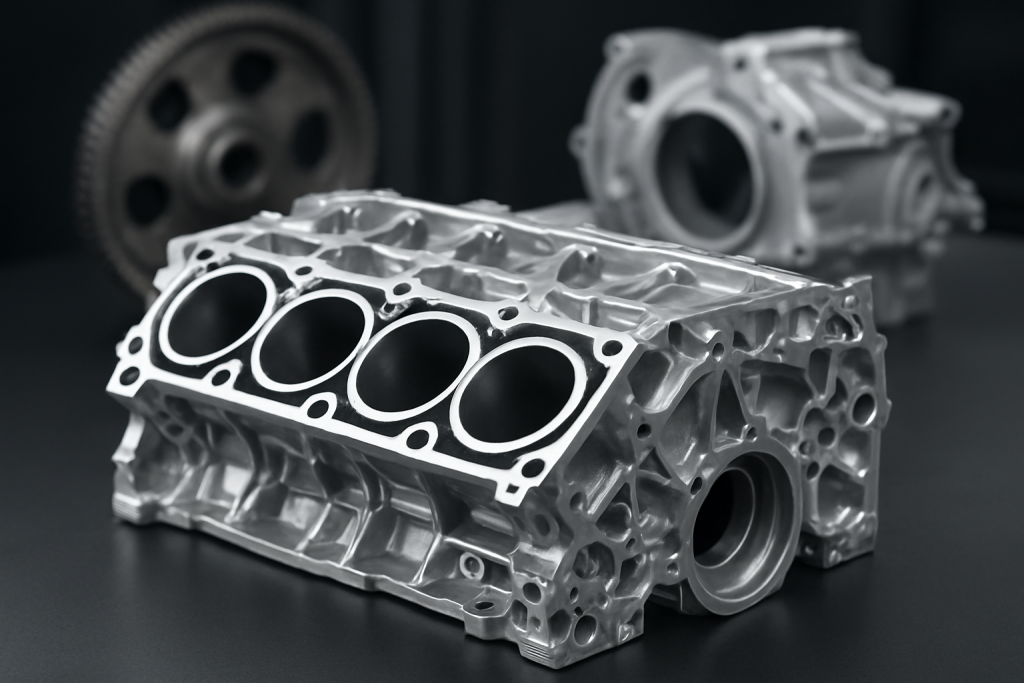

Optimize your designs for cost efficiency, manufacturability, and superior performance with Kingsmg CNC’s DFM expertise.

At Kingsmg CNC, we don’t just manufacture parts — we partner with engineers and innovators to optimize designs for CNC machining.

Our Design for Manufacturing (DFM) Guide provides best practices and engineering insights to ensure your parts are not only manufacturable, but also cost-effective and high-performing.

What is DFM?

Design for Manufacturing (DFM) is the process of designing components with manufacturing constraints in mind. By considering machining capabilities, tolerances, and material choices during the design phase, you can:

Reduce production costs

Shorten lead times

Improve product quality

Minimize design revisions and failures

Our Prototyping Capabilities

📐 Tolerances

- Standard tolerance: ±0.005 in (±0.127 mm)

- Apply tighter tolerances only where necessary to reduce costs

🔄 Wall Thickness

- Minimum recommended thickness: 1.0 mm for metals, 1.5 mm for plastics

- Avoid overly thin walls that may warp or break

🌀 Holes & Threads

- Minimum hole diameter: 1.0 mm

- Standard thread sizes recommended; avoid custom threads when possible

🏗️ Undercuts & Internal Corners

- Add fillets (radius ≥ tool diameter) to internal corners

- Avoid sharp corners to reduce tool wear and machining time

⚖️ Part Size & Complexity

- Max part size: 1000 mm × 500 mm × 500 mm

- Consider multi-axis machining for complex geometries

🎨 Surface Finish Considerations

- Define functional vs. cosmetic surfaces clearly

- Choose finishes such as anodizing, bead blasting, or electropolishing based on application

Common Design Mistakes to Avoid

❌ Overly tight tolerances across all features

❌ Unsupported thin walls or long slender features

❌ Excessively deep cavities leading to deflection

❌ Non-standard threads or hole sizes

❌ Over-specifying cosmetic finishes on non-critical surfaces

Why Kingsmg CNC for DFM?

✅ Engineering support from concept to production

✅ ISO-compliant quality management

✅ Experienced in multi-industry applications

✅ Faster prototyping and smoother transition to mass production

✅ Free DFM review with every quotation