Introduction

Manufacturing in the 21st century relies heavily on precision, speed, and efficiency, and CNC (Computer Numerical Control) machining stands at the heart of this transformation. By combining automation with advanced tooling, CNC systems enable manufacturers to produce complex, high-quality parts with consistency across industries—from aerospace and automotive to medical and consumer electronics.

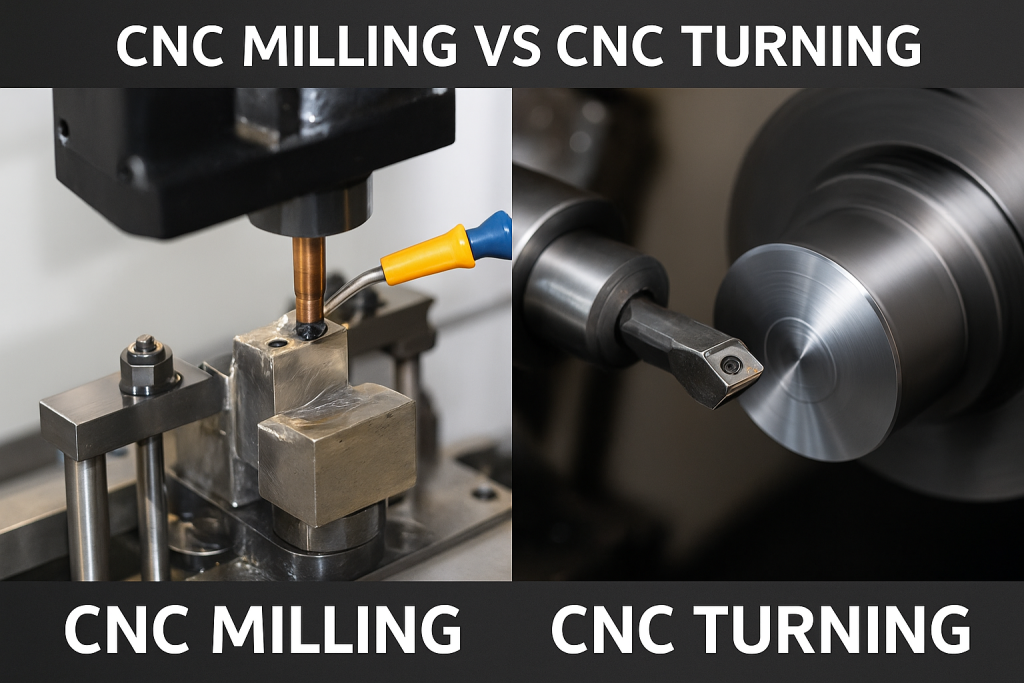

Among the numerous CNC processes, CNC milling and CNC turning are the most widely used. While both involve material removal through controlled cutting, their principles, tooling, and applications differ significantly. Knowing these differences is critical for engineers, product designers, and decision-makers tasked with choosing the best machining process for their needs.

This comprehensive guide will explain:

-

How CNC milling and CNC turning work

-

Their advantages and disadvantages

-

The core differences in design and operation

-

Applications across industries

-

How companies like KingsMG help manufacturers adopt the right machining solutions

By the end, you’ll have a complete understanding of which process to use and why these techniques remain essential in modern manufacturing.

What is CNC Milling?

CNC milling is a subtractive machining process where rotary cutting tools remove material from a stationary workpiece. The workpiece is clamped in place, while the cutting tool rotates at high speeds and moves along multiple axes (X, Y, Z, and beyond) to carve the desired geometry.

This flexibility makes CNC milling one of the most versatile machining methods, capable of producing slots, pockets, flat surfaces, threaded holes, and even complex 3D contours.

Key Features of CNC Milling

-

Multi-Axis Motion – CNC mills range from 3-axis machines to advanced 5-axis systems. More axes mean more complex cuts and greater efficiency.

-

Variety of Tools – End mills, face mills, ball-nose cutters, and drills enable different types of cuts, from flat surfaces to intricate details.

-

Precision Material Removal – Tools cut away material incrementally until the finished shape is achieved.

Advantages of CNC Milling

-

Versatility – Can handle simple parts, detailed 3D geometries, and multi-feature designs.

-

High Precision – Tight tolerances and detailed machining are achievable.

-

Multi-Operation Capability – One setup may allow drilling, contouring, slotting, and tapping.

Disadvantages of CNC Milling

-

Slower for High Volumes – Tool changes and complex paths make milling slower compared to turning.

-

Higher Cost – Equipment and tooling are expensive, especially for small production runs.

What is CNC Turning?

CNC turning is a subtractive process used primarily to create cylindrical or symmetrical parts. Unlike milling, here the workpiece rotates while the cutting tool remains stationary and moves along linear axes (X and Z).

This method is perfect for producing shafts, pins, bushings, nozzles, and other round parts. CNC turning is performed on CNC lathes or turning centers.

Key Features of CNC Turning

-

Rotating Workpiece – Instead of the tool, the part spins at high speed.

-

Fewer Axes – Typically limited to 2 axes (X and Z), making it simpler than milling.

-

Ideal for Round Profiles – Cones, cylinders, grooves, and threads are produced efficiently.

Advantages of CNC Turning

-

Speed – Excellent for fast production of round parts.

-

Lower Cost – More economical for cylindrical components compared to milling.

-

Tool Durability – Reduced wear leads to less downtime.

Disadvantages of CNC Turning

-

Shape Limitations – Not suitable for parts with intricate 3D geometries.

-

One-Sided Removal – Primarily works along one axis, limiting complexity.

CNC Milling vs CNC Turning: Key Differences

While both processes deliver precision machining, their principles differ. Here’s a clear comparison:

| Feature | CNC Milling | CNC Turning |

|---|---|---|

| Motion | Rotary tool moves along multiple axes (X, Y, Z, A, B) | Workpiece rotates, tool moves along X and Z |

| Best For | Complex 3D shapes, slots, and holes | Cylindrical parts, shafts, cones |

| Tools Used | End mills, face mills, drills | Single-point cutting tools, boring bars |

| Setup Complexity | High (due to multiple tools and operations) | Lower, simpler setup |

| Workpiece | Fixed, clamped | Rotating |

| Cutting Speed | Slower, depending on part complexity | Faster for symmetrical parts |

| Material Removal | Multi-directional | Primarily one direction |

In short, milling is versatile but slower, while turning is faster but limited in geometry.

How CNC Milling Works – Step by Step

-

Programming – A CAD/CAM program defines toolpaths and operations.

-

Workholding – The part is clamped using vises, jigs, or fixtures.

-

Tool Selection – Depending on the geometry, multiple tools may be required.

-

Machining – The tool rotates and removes material along programmed paths.

-

Finishing – Secondary cuts refine the part’s surface and detail.

Milling’s biggest advantage is its ability to produce multiple features in a single setup.

How CNC Turning Works – Step by Step

-

Programming – Tool movement, spindle speeds, and feed rates are defined.

-

Setup – The part is mounted on the spindle chuck.

-

Tool Selection – Single-point tools, drills, or boring bars are chosen.

-

Turning Process – The rotating part meets the stationary tool, shaping it.

-

Finishing – Grooving, threading, and polishing are applied as needed.

Turning’s strength lies in its speed and cost-effectiveness for cylindrical parts.

Applications of CNC Milling

-

Aerospace – Turbine blades, wing ribs, landing gear, and structural components.

-

Automotive – Engine blocks, transmission cases, and precision detail parts.

-

Medical – Surgical implants, prosthetics, and diagnostic equipment.

-

Electronics – Housings, enclosures, and heat sinks.

-

Tool and Die – Dies, molds, and tooling for other industries.

Applications of CNC Turning

-

Automotive – Shafts, axles, and cylindrical drive components.

-

Aerospace – Nozzles, struts, and landing gear pins.

-

Industrial Equipment – Bushings, pistons, gears, and couplings.

-

Medical – Syringes, valves, and cylindrical implants.

-

Consumer Goods – Appliance shafts, sports equipment, and decorative pieces.

Industry Perspective: Choosing the Right Process

Manufacturers rarely choose between milling and turning in isolation. Instead, they combine both processes in hybrid machining centers or across complementary workflows.

For example:

-

Automotive manufacturers mill engine blocks but turn shafts and gears.

-

Aerospace suppliers mill wing structures and turn turbine shafts.

-

Medical device makers mill implants and turn surgical needles.

The decision depends on part geometry, required tolerances, cost, and volume.

KingsMG: Driving CNC Innovation

At KingsMG, we help manufacturers select and implement the right CNC machining solutions to achieve maximum productivity and precision. Our expertise covers:

-

Advanced CNC Milling – Multi-axis milling for complex aerospace and medical components.

-

High-Speed CNC Turning – Automated turning centers for automotive and industrial parts.

-

Hybrid Solutions – Integrated systems combining milling and turning.

-

Workholding & Fixtures – Smart jigs and fixtures to reduce setup times and improve accuracy.

-

Consulting & Training – Helping manufacturers adopt best practices and stay ahead of Industry 4.0.

By leveraging KingsMG’s advanced capabilities, manufacturers reduce cycle times, improve first-part accuracy, and stay competitive in global markets.

Conclusion

CNC machining has redefined modern manufacturing, and CNC milling and CNC turning remain its most powerful pillars.

-

Milling excels in complexity – best for detailed, multi-feature parts across aerospace, medical, and electronics.

-

Turning excels in speed and cost – ideal for cylindrical, symmetrical parts in automotive, industrial, and consumer goods.

By understanding their differences, strengths, and limitations, manufacturers can make informed decisions that balance cost, precision, and efficiency.

With expert support from KingsMG, you can ensure your machining strategy is future-ready, blending innovation, accuracy, and productivity for success in today’s fast-moving industrial landscape.