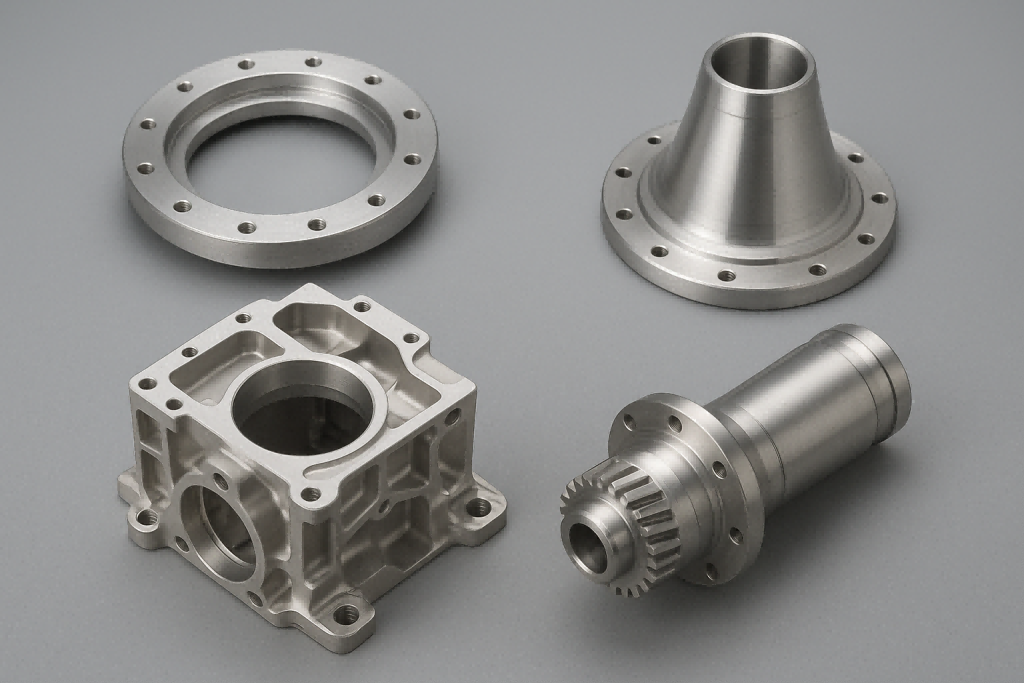

Technological advancements have long since enabled us to print three-dimensional objects. With the continued decrease in the cost of 3D printers, the technique has gained remarkable momentum — transforming digital designs into physical objects is now more accessible than ever before.

In this article, KingsMG explains in detail the main 3D metal printing processes and materials so you can better evaluate their costs, benefits, and potential for your own applications.

Table of Contents

-

Types of 3D Metal Printing Techniques

-

Material Selection for Metal 3D Printing

-

Factors Affecting Material Selection

-

Common Metals Used in 3D Printing

-

Post-Processing Techniques for Metal 3D Printed Parts

-

Benefits and Limitations of Metal 3D Printing

-

The Pros of 3D Metal Printing

-

The Cons of 3D Metal Printing

-

Endnote

Types of 3D Metal Printing Techniques

The specific technique used to 3D print a metal object depends on your project’s scale, geometry, and required physical properties. Here are some of the most common methods:

1. Powder Bed Fusion

In this process, a thin layer of metal powder is spread across a build plate, and a high-powered laser selectively melts the powder to form each layer of the object. The build platform then lowers, and another layer of powder is added. This continues until the full 3D structure is complete.

This method includes two major subtypes: Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS).

-

SLM fully melts the metal powder, typically using pure metals with uniform melting points.

-

DMLS, by contrast, works with metal alloys that have multiple melting temperatures, fusing them at the molecular level.

Because of its precision and control, Powder Bed Fusion is widely used to produce turbine blades, rocket engine components, medical implants, jewelry, and fine art sculptures.

2. Binder Jetting

Binder Jetting builds metal objects by alternating layers of powder and a liquid binding agent. Once the desired geometry is achieved, the excess powder is removed, and the object is sintered in a furnace to fuse the metal particles.

The process is cost-effective and ideal for large and complex components. Applications include architectural models, aircraft fuselage sections, engine parts, and even biomedical scaffolds.

3. Directed Energy Deposition (DED)

DED deposits molten metal layer by layer to form an object. A high-powered laser or electron beam melts metal powder or wire directly onto a substrate, building up the geometry as it proceeds.

This method is highly versatile and allows for the creation or repair of large, high-strength metal parts. It’s commonly used in aerospace, defense, automotive, and power-generation industries.

4. Laminated Object Manufacturing (LOM)

LOM, a type of sheet lamination process, can also be adapted for metals. The object is sliced into layers, which are printed on thin sheets of metal foil coated with adhesive. Each sheet is then laser-cut and stacked under pressure to form the final part.

While LOM parts require post-processing (such as sanding or polishing), this method is cost-efficient and suitable for prototyping, mock-ups, and artistic or educational applications.

5. Ultrasonic Additive Manufacturing (UAM)

UAM also stacks thin metal foils, but instead of using heat or pressure, it employs ultrasonic vibrations to bond the metal layers at the atomic level. The result is a strong, low-density part with exceptional bonding strength.

UAM is used in aircraft components, biomedical implants, electronic devices, and automotive systems — anywhere lightweight yet durable materials are essential.

Material Selection for Metal 3D Printing

Material selection in 3D printing is critical and depends on the chosen process, desired properties, and application environment.

Factors Affecting Material Selection

1. Application Requirements

Each application has unique requirements. For example:

-

Titanium is ideal for biomedical implants because it’s biocompatible and corrosion-resistant.

-

Aluminum suits aerospace components, being lightweight and cost-effective.

-

Copper is used in electrical parts due to its excellent conductivity.

2. Compatibility with Printing Technology

Not every metal works with every technique:

-

Brittle metals like cast iron may crack during DED.

-

Metals with extremely high melting points (e.g., tungsten) require too much energy to print efficiently.

-

Reactive or magnetic metals can pose challenges in processes like binder jetting or powder bed fusion.

3. Cost, Availability, and Post-Processing

Expensive metals such as gold or platinum are reserved for jewelry and high-value electronics. Other metals — like titanium or cobalt-chrome — often require significant post-processing to address rough finishes or warping.

Common Metals Used in 3D Printing

Here are some of the most frequently used metals in 3D printing today:

-

Stainless Steel – Durable and versatile; ideal for medical, aerospace, and automotive parts.

-

Aluminum – Lightweight and corrosion-resistant; used in aerospace and automotive components.

-

Copper – Excellent electrical and thermal conductor; ideal for electronics and heat exchangers.

-

Gold, Silver, Platinum – Used for luxury jewelry and collectible items.

-

Cobalt-Chrome Alloys – Biocompatible; widely used for dental and medical implants.

Post-Processing Techniques for Metal 3D Printed Parts

Metal 3D printed parts often require finishing to improve surface quality, mechanical strength, or appearance. Common post-processing methods include:

-

Machining – Removes excess material and refines shape and surface finish.

-

Polishing – Buffs and smooths surfaces for aesthetic and functional improvement.

-

Heat Treatment – Enhances strength and flexibility while preventing oxidation.

-

Stress-Relief Annealing – Reduces internal stresses to prevent warping or cracking.

-

Surface Coating – Adds protective or decorative layers.

-

Electroplating – Deposits a metal coating to enhance durability or conductivity.

-

Hot Isostatic Pressing (HIP) – Uses high pressure and temperature to eliminate porosity and increase density.

Benefits and Limitations of Metal 3D Printing

Understanding both sides of metal 3D printing helps manufacturers make informed decisions about feasibility and investment.

The Pros of 3D Metal Printing

1. Design Flexibility

Metal 3D printing enables highly complex geometries impossible to achieve with conventional methods. Custom biomedical implants, lightweight aerospace structures, and intricate jewelry all benefit from this freedom of design.

2. Rapid and Accurate Prototyping

With 3D printing, rapid prototyping accelerates innovation by allowing designers and engineers to visualize and test concepts quickly before mass production.

3. Efficient Resource Utilization

As an additive manufacturing process, 3D printing minimizes waste by using only the necessary material. It also reduces logistics and storage costs since printing can be done locally.

4. Precision and Repeatability

The layer-by-layer approach ensures micron-level accuracy, ideal for medical devices and electronic components. Moreover, consistent calibration guarantees high repeatability — crucial for uniform product quality.

The Cons of 3D Metal Printing

Despite its advantages, metal 3D printing still faces notable challenges:

-

Limited material options — some metals (like zinc or lead) are impractical to print.

-

Restricted build volumes, limiting large-scale production.

-

Rough surface finishes, often requiring post-processing.

-

Slow production speed, especially for large or detailed parts.

-

High energy consumption and costs due to equipment and raw materials.

-

Extensive post-processing needs, depending on material and method used.

Endnote

Metal 3D printing has become a transformative force in modern manufacturing, unlocking designs and applications once considered impossible. As the technology advances, costs continue to drop and accessibility improves — making it an increasingly viable option for industries worldwide.

At KingsMG, we believe the future of metal fabrication lies in innovation, precision, and sustainability. Whether you’re developing aerospace components, medical implants, or artistic creations, metal 3D printing offers the flexibility and performance to bring your ideas to life.