Brass is one of the most widely used and versatile alloys in modern manufacturing and design. Known for its bright golden appearance and excellent mechanical properties, brass has found its way into countless industries — from plumbing and musical instruments to fine jewelry and art sculptures. One of the key physical properties that define brass’s performance is its density. Understanding brass density not only helps engineers and designers select the right material for a given application but also provides valuable insights into its composition, strength, and functionality.

In this article, we’ll explore what brass density means, the factors that influence it, and how it determines the metal’s performance. We’ll also take a deep dive into brass applications in the casting industry and its growing popularity in jewelry and decorative accessories.

What Is Brass?

Brass is a metal alloy primarily composed of copper (Cu) and zinc (Zn). The proportion of these two elements can vary significantly depending on the desired characteristics. For instance:

-

High-copper brass (around 70% Cu, 30% Zn) is more ductile and corrosion-resistant.

-

High-zinc brass (up to 40% Zn) offers greater strength and hardness but less corrosion resistance.

Other elements such as tin, lead, iron, or aluminum may also be added in small quantities to modify specific properties like machinability, hardness, or color tone. This versatility makes brass an ideal choice for numerous industrial and artistic applications.

Understanding Brass Density

Density refers to the mass of a material per unit volume, usually expressed in grams per cubic centimeter (g/cm³) or kilograms per cubic meter (kg/m³). For brass, the density depends largely on its composition.

On average, the density of brass ranges between 8.2 and 8.7 g/cm³.

This variation occurs because copper has a density of about 8.96 g/cm³, while zinc’s density is 7.13 g/cm³. Therefore, alloys with a higher copper content tend to be denser, while those with more zinc are lighter.

| Brass Type | Composition (Cu-Zn) | Approx. Density (g/cm³) |

|---|---|---|

| Cartridge Brass | 70-30 | 8.53 |

| Muntz Metal | 60-40 | 8.47 |

| Naval Brass | 60-39-1 (Cu-Zn-Sn) | 8.44 |

| Leaded Brass | 59-39-2 (Cu-Zn-Pb) | 8.50 |

| Red Brass | 85-15 | 8.83 |

These density values influence not only the weight of brass components but also their thermal conductivity, sound resonance, and structural behavior under stress — all crucial factors in casting and design applications.

Why Brass Density Matters

-

Design and Engineering Precision

In precision engineering, understanding material density helps determine the overall mass and balance of parts. For example, when manufacturing valves, gears, or decorative fittings, engineers must ensure that the final weight matches design expectations. -

Casting Control

During the casting process, knowing the density allows foundry workers to accurately calculate the amount of molten brass required to fill a mold. This reduces waste, ensures consistency, and improves cost efficiency. -

Aesthetic and Functional Balance

In jewelry and accessories, brass’s density affects how pieces feel when worn. A solid, slightly heavy feel can communicate quality and durability, while lighter alloys are preferred for large statement designs.

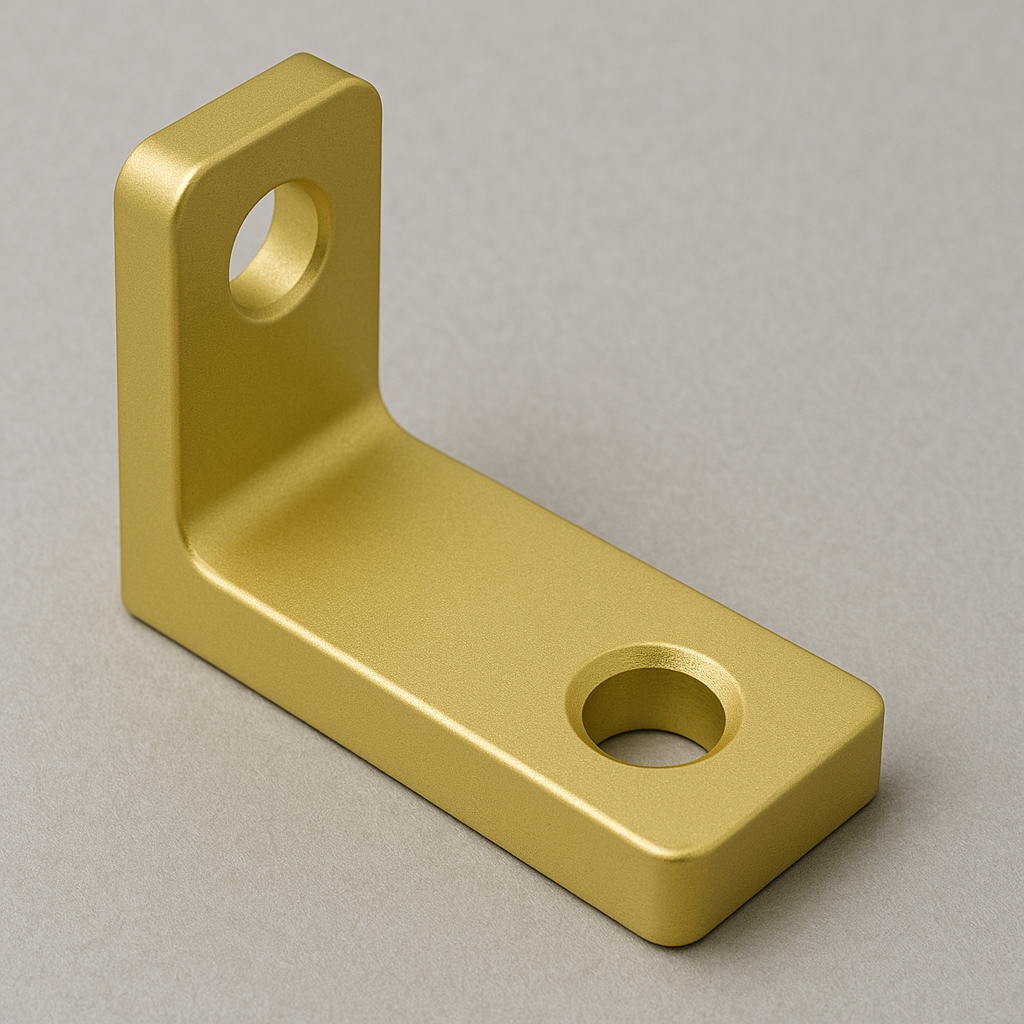

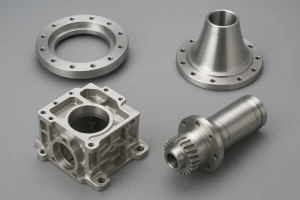

Brass in the Casting Industry

The casting industry has long relied on brass for its excellent mold-filling ability, dimensional stability, and ease of finishing. Brass castings can achieve fine detail and smooth surfaces, making them ideal for both functional components and ornamental objects.

1. Advantages of Brass in Casting

-

Excellent Fluidity

Brass melts between 900°C and 940°C, which is lower than pure copper. This allows the molten metal to flow easily into intricate mold designs, ensuring accurate replication of patterns and fine details. -

Corrosion Resistance

Brass exhibits natural resistance to oxidation and corrosion, particularly from water and mild chemicals. This makes it ideal for casting parts exposed to moisture — such as plumbing fixtures, marine hardware, and pump components. -

Machinability and Finish

After casting, brass parts can be easily machined, polished, or electroplated. Its surface can be buffed to a mirror-like shine or left with a brushed antique look, depending on the intended aesthetic. -

Dimensional Stability

Brass maintains tight tolerances after cooling, reducing the need for post-casting corrections. This stability makes it a preferred material for precision engineering applications.

2. Common Brass Casting Applications

-

Industrial Valves and Fittings

Brass’s durability and corrosion resistance make it perfect for producing valves, pipe connectors, and faucets that endure high pressure and varying temperatures. -

Marine Hardware

Brass castings are commonly used for ship fittings, propellers, and decorative elements on boats due to their resistance to saltwater corrosion. -

Architectural Elements

Brass is popular for casting door handles, railings, nameplates, and decorative sculptures. Its golden luster brings both elegance and durability to architectural design. -

Electrical Components

Certain brass alloys offer good electrical conductivity, making them suitable for electrical connectors, switch parts, and terminals.

3. Modern Innovations in Brass Casting

With advancements in casting technology, such as investment casting and 3D-printed sand molds, brass components today can achieve incredible precision and artistic complexity. Many foundries are also shifting toward lead-free brass alloys, promoting sustainability and meeting global environmental standards.

Brass in Jewelry and Decorative Accessories

Beyond its industrial uses, brass holds a special place in the world of fashion and decorative arts. Its rich, warm hue — reminiscent of gold — makes it a cost-effective and beautiful material for designers and artisans.

1. Aesthetic Appeal

Brass offers a timeless golden color that can range from bright yellow to reddish gold, depending on its copper content. This makes it an ideal substitute for gold in fashion jewelry, vintage pieces, and bohemian accessories. When polished, it gleams brilliantly; when aged, it develops an attractive natural patina that adds depth and character.

2. Versatility in Design

Brass is soft enough to be shaped into intricate forms yet durable enough to hold fine details, making it suitable for:

-

Earrings, necklaces, bracelets, and rings

-

Decorative buckles, buttons, and clasps

-

Watch cases and eyewear frames

-

Home décor items such as candle holders and ornaments

Artisans often pair brass with other materials — wood, leather, or gemstones — to create unique mixed-media designs. Because of its adaptability, brass can seamlessly complement both traditional and contemporary aesthetics.

3. Surface Treatments and Finishes

To enhance durability and prevent tarnishing, brass accessories are often coated or treated using:

-

Electroplating (gold, silver, or rhodium) for a luxurious shine and corrosion protection.

-

Lacquering or waxing to maintain a polished appearance and slow down oxidation.

-

Antique or brushed finishes to achieve a vintage or rustic look.

These finishing techniques not only preserve the visual appeal of brass but also expand its use in modern fashion and interior design.

4. Eco-Friendly and Recyclable Material

In today’s sustainable design movement, brass stands out as a recyclable and eco-friendly material. Most jewelry and accessory makers source brass from recycled scrap metal, reducing environmental impact. Its longevity also means that brass pieces can last for decades, even centuries, when properly cared for.

The Balance Between Beauty and Function

Whether in heavy industrial molds or delicate earrings, brass strikes a rare balance between aesthetic beauty and practical functionality. Its moderate density contributes to that harmony — heavy enough to feel substantial and durable, yet light enough for comfort and versatility.

For engineers, brass’s density provides predictability and strength. For artists and jewelers, it offers warmth, color, and expression. This duality is what keeps brass relevant in both manufacturing and art after centuries of use.

Conclusion

Brass density — typically around 8.4 to 8.7 g/cm³ — may seem like a technical detail, but it lies at the heart of why brass is so widely admired and utilized. This balance of weight, strength, and malleability makes brass a cornerstone material in industries ranging from heavy casting to fine jewelry design.

In the casting industry, brass provides precision, durability, and aesthetic flexibility. In the world of fashion and accessories, it brings elegance, warmth, and sustainable value. Together, these characteristics make brass an enduring material that continues to bridge the gap between functionality and beauty — a true testament to the art and science of metallurgy.