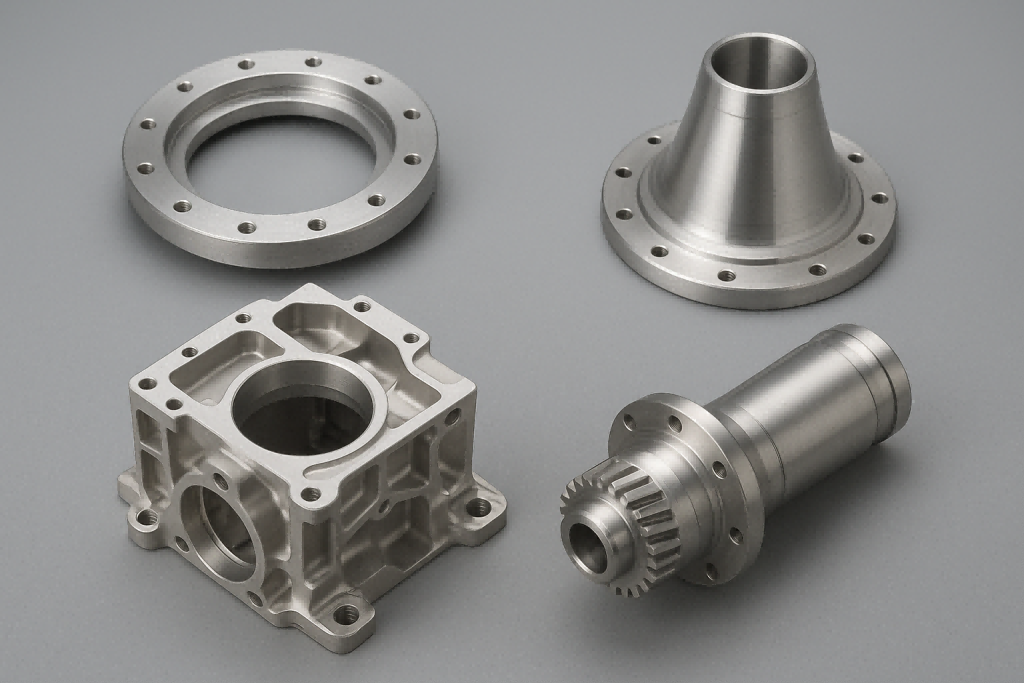

In today’s fast-paced manufacturing world, precision, reliability, and speed are essential for bringing products from concept to market. KingsMG provides custom online CNC machining services that empower engineers, designers, and manufacturers to produce parts that meet exact specifications — whether for prototypes, small batches, or high-volume production.

With a global network of certified machine shops and an advanced instant quoting system, KingsMG connects customers to the best CNC machining resources available. From simple components to complex, high-tolerance assemblies, KingsMG ensures high-quality parts delivered on time and at competitive prices.

What Is CNC Machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that uses automated, high-speed cutting tools to shape raw materials such as metal or plastic into precise parts. Common CNC machines include 3-axis, 4-axis, and 5-axis milling machines, as well as lathes and routers.

During CNC machining, a digital CAD (Computer-Aided Design) model of a part is converted into G-code instructions. These instructions control the motion of tools and the speed of cutting, enabling the creation of parts with intricate geometries and tight tolerances.

CNC machining is used across many industries — from aerospace and medical to robotics, automotive, and electronics — thanks to its versatility, accuracy, and ability to work with a wide variety of materials.

KingsMG offers machining services for over 40 different metals and plastics, including aluminum, titanium, stainless steel, brass, acetal (Delrin), PEEK, and Teflon.

Why Use KingsMG for CNC Machining?

1. Comprehensive CNC Services

KingsMG offers an end-to-end CNC machining experience, from quoting to production and quality inspection. Services include:

-

Rapid Prototyping: Ideal for fast design validation and functional testing.

-

Small-Batch Machining: Perfect for short production runs and custom projects.

-

High-Volume Manufacturing: Reliable large-scale production with consistent quality.

Every order is fully managed by KingsMG, ensuring seamless communication, reliable delivery, and cost transparency from start to finish.

2. Quality Assurance You Can Trust

KingsMG upholds rigorous quality control standards throughout its manufacturing network. The company’s certified facilities maintain:

-

ISO 9001:2015

-

ISO 13485 (Medical devices)

-

IATF 16949:2016 (Automotive)

-

AS9100D (Aerospace)

-

ITAR registration (Defense compliance)

Customers can request material certifications, Certificates of Conformance (CoCs), inspection reports, and hardware traceability. Each part is inspected for dimensional accuracy and surface finish before shipment, ensuring consistency across every order.

3. Fast Instant Quoting and DFM Feedback

With KingsMG’s Instant Quoting System, users can upload CAD files directly to receive:

-

Real-time pricing

-

Lead time estimates

-

Design-for-manufacturability (DFM) feedback

This automation allows customers to optimize part designs, reduce manufacturing costs, and accelerate time to market — without back-and-forth communication delays.

KingsMG CNC Machining Capabilities

CNC Milling

KingsMG’s custom CNC milling services produce precision parts from both metals and plastics. Capabilities include:

-

Quick-turn prototypes and production runs in days

-

Parts up to 80” x 48” x 24” (2032 x 1219 x 610 mm)

-

Tight tolerances down to ±0.001” (0.025 mm)

-

Free standard domestic shipping and competitive global pricing

CNC Turning

For cylindrical components such as shafts, bushings, and threaded parts, CNC turning provides accuracy and surface quality unmatched by manual processes. KingsMG can produce turned parts up to:

-

62” (1575 mm) in length

-

32” (813 mm) in diameter

CNC Routing

KingsMG’s CNC routing services are ideal for cutting large sheets of wood, plastic, or composite material. High-speed routers ensure clean edges and minimal waste — perfect for aerospace, signage, and enclosure applications.

High-Volume CNC Production

For customers needing thousands of units, KingsMG offers high-volume CNC machining with efficient scaling, consistent quality, and just-in-time delivery. Automated production lines and dedicated quality checks ensure repeatable accuracy across every batch.

CNC Machining Materials

Metal CNC Materials

KingsMG’s CNC machining network supports a broad range of metals, including:

-

Aluminum Alloys (6061, 7075, 2024, etc.) – lightweight, corrosion-resistant, and affordable.

-

Stainless Steel Alloys (303, 304, 316, 17-4 PH) – excellent strength and durability.

-

Brass & Bronze Alloys – great for electrical conductivity and aesthetic appeal.

-

Copper & Zinc Alloys – used in electronics and heat transfer applications.

-

Titanium Alloys (Grade 2, 5) – ideal for aerospace and medical components.

-

Steel Alloys (4140, 1018, 4340) – tough materials for structural parts.

Plastic CNC Materials

For lightweight, non-metal applications, KingsMG offers precision machining of plastics such as:

-

ABS – tough and cost-effective.

-

Delrin (Acetal) – strong, wear-resistant, and low friction.

-

Nylon (PA 6/6) – flexible and durable.

-

PEEK – high-performance thermoplastic with superior chemical and heat resistance.

-

Polycarbonate (PC) – impact-resistant and transparent.

-

Teflon (PTFE) – excellent for chemical resistance and low friction.

-

HDPE, ULTEM, PVC, Polypropylene, and Acrylics – for specialized applications.

Finishing Options for CNC Machined Parts

KingsMG offers a wide selection of surface finishing processes to improve part performance and aesthetics. These include:

-

As-Milled (Standard) – 125 Ra or better surface finish

-

Bead Blasting – uniform matte texture

-

Tumbling – smooths sharp edges

-

Anodizing (Type II & III) – corrosion and wear resistance

-

Titanium Anodizing – decorative and functional oxide layers

-

PTFE-Impregnated Hard Anodize – low friction, enhanced durability

-

Chem Film (Chromate Conversion) – for aluminum protection

-

Passivation – removes surface contaminants from stainless steel

-

Powder Coating – durable, colored surface finish

-

Electropolishing / Electroless Nickel / Gold / Silver / Zinc Plating – for conductivity, appearance, and corrosion protection

CNC Machining Design Guidelines

To ensure manufacturability and cost efficiency, KingsMG recommends the following design considerations:

| Feature | Design Tip |

|---|---|

| Internal Corners | Use fillets 0.020–0.050” larger than tool radius. |

| Floor Fillets | Keep smaller than corner fillets to allow the same tool to reach all surfaces. |

| Undercuts | Use standard sizes and position away from corners for tool access. |

| Tapped Hole Depth | Allow extra clearance beyond the thread depth. |

| Complexity | Simplify small cuts to reduce machining time and cost. |

Following these guidelines ensures efficient machining and helps reduce turnaround time.

CNC Machining Tolerances

KingsMG maintains tight machining tolerances to meet customer requirements:

-

General Tolerances: ±0.005” (±0.127 mm) for metals; ±0.010” (±0.254 mm) for plastics

-

Precision Tolerances: Up to ±0.001” or tighter upon request

-

Minimum Feature Size: 0.020” (0.50 mm), depending on material and geometry

-

Edge Condition: Sharp edges are deburred by default

-

Threads: Any standard or custom thread sizes available

Advantages of CNC Machining

CNC machining offers numerous benefits over traditional manufacturing methods:

-

High Precision and Repeatability: Achieves tight tolerances with consistent results.

-

Scalability: From one-off prototypes to 10,000+ production runs.

-

Speed: Parts can be produced in as little as 1–3 days.

-

Material Versatility: Works with metals, plastics, and composites.

-

Durability: Retains mechanical strength since material properties aren’t altered by heat.

-

Automation: Machines can operate 24/7 for uninterrupted production.

These advantages make CNC machining ideal for creating end-use parts, functional prototypes, and specialized tooling.

Challenges of CNC Machining

While CNC machining is highly capable, it also presents some challenges:

-

Setup Time: Initial programming and fixturing can be time-consuming.

-

Material Waste: Subtractive nature leads to scrap material.

-

Complex Geometries: Some internal features are difficult to reach with cutting tools.

-

Cost of Equipment: Precision machines and skilled operators require investment.

Despite these challenges, KingsMG’s experience and design-for-manufacturability feedback minimize inefficiencies and help customers achieve cost-effective results.

CNC Machining Applications

CNC machining supports a wide range of industrial uses:

-

Rapid Prototyping: Quickly validate designs using affordable materials like aluminum 6061 or ABS.

-

Rapid Tooling: Create molds, dies, and jigs from durable materials such as stainless steel or aluminum 5052.

-

End-Use Production: Manufacture final-use parts with performance finishes and certifiable materials.

-

Aerospace & Medical: Produce mission-critical components with extreme precision and compliance.

Summary

CNC machining remains one of the most reliable and flexible manufacturing processes in the modern world. Whether you need a one-off prototype or a high-volume production run, KingsMG provides the technology, expertise, and quality assurance to make your project a success.

KingsMG combines an advanced instant quoting platform, a global network of certified suppliers, and industry-leading quality systems to deliver custom CNC machined parts with unmatched speed and precision.

Visit KingsMG’s website today to request an instant CNC machining quote or consult our experts for your next design or production challenge.

Disclaimer:

The information provided on this page is for educational purposes only. KingsMG makes no guarantee, explicit or implied, regarding the accuracy or completeness of this content. Product specifications, tolerances, and materials should always be verified with KingsMG prior to production.