Learn about the 10 key categories of 3D printer components and what each one does.

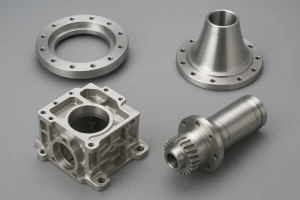

3D printing has evolved from a niche hobby into one of the most transformative manufacturing technologies in the world. Whether used for rapid prototyping, product design, or full-scale production, every 3D printer—regardless of brand or price—relies on a set of fundamental parts that make the printing process possible. Understanding these parts is essential for maintenance, upgrades, and achieving high-quality prints.

This guide explores the 10 main types of 3D printing machine components, explaining what they do, how they work, and how users can optimize or upgrade them for better performance.

1. Motherboard (Controller Board)

The motherboard, or controller board, acts as the brain of the 3D printer. It connects and controls every electronic component, interpreting software instructions into physical movements.

-

Processor: Executes G-code commands, converting them into instructions for the printer’s motors and sensors. Most modern printers use 32-bit processors for faster and more precise control.

-

Connectors: Interface between components such as motors, heaters, and sensors. These often include terminal blocks, USB ports, and cable connectors.

-

Stepper Drivers: Regulate the current to each motor, ensuring smooth and accurate motion on the X, Y, and Z axes.

-

Communication Ports: Allow G-code to be uploaded via Wi-Fi, SD card, or USB connection.

Upgrading the motherboard can improve performance, but compatibility and power limits must be checked carefully before installation.

2. Power Supply Unit (PSU)

The Power Supply Unit provides stable energy to all printer components. It converts high-voltage AC from a wall outlet into low-voltage DC suitable for the motherboard, motors, and heaters.

When adding high-powered components—like larger heaters or additional extruders—upgrading the PSU is sometimes necessary. Always verify that the motherboard can handle the increased wattage to prevent electrical failure.

3. Frame

The frame is the structural skeleton of the printer. It holds all mechanical and electronic components in alignment and resists vibration during operation.

Frames are typically made of aluminum, steel, or plastic composites. A more rigid frame improves print accuracy and allows faster printing speeds without sacrificing quality.

Upgrading or reinforcing the frame—by adding gussets or corner brackets—can significantly enhance stability and precision.

4. User Interface

The user interface (UI) is how users communicate with their 3D printer. Entry-level printers often feature a small LCD screen and control knob, while advanced models offer touchscreen displays or wireless connectivity for remote control.

Through the UI, users can load print files, adjust temperatures, and monitor progress. Printers connected to a computer or network can also be managed through specialized software.

When upgrading to a new UI screen, ensure firmware compatibility and sufficient power output from the motherboard.

5. Connectivity

3D printers receive print instructions through different connectivity methods, such as:

-

SD Card: The most common and reliable method.

-

USB Cable: Allows real-time control from a connected computer.

-

Wi-Fi or Ethernet: Enables remote file uploads and monitoring.

Many modern machines offer cloud-based control, allowing users to send files directly to the printer from design software.

6. Extruder

The extruder is one of the most critical components of a 3D printer. It is responsible for feeding filament, melting it, and depositing it layer by layer.

There are three main extruder configurations:

-

Direct Drive: The filament feed motor is mounted directly above the hot end, improving control for flexible materials.

-

Bowden: The motor is separated from the hot end and pushes filament through a tube, reducing print head weight for faster movement.

-

Dual Extrusion: Uses two extruders for multi-material or multi-color printing.

Switching from direct drive to Bowden or adding a second extruder requires verifying the motherboard’s available stepper driver connections and power capacity.

7. Motion Controllers

Motion controllers convert electronic commands into physical movement. Stepper motors drive each axis (X, Y, Z) with extreme precision, while belts or threaded rods translate rotational motion into linear motion.

-

Belts are used for the X and Y axes to allow high-speed movement.

-

Lead screws are used for the Z-axis, providing accuracy and stability.

While motion systems rarely need upgrades, maintaining proper belt tension and lubrication is key for long-term performance.

8. Print Materials

Fused Deposition Modeling (FDM) printers typically use filament spools made of thermoplastic materials. Common filament types include:

-

PLA (Polylactic Acid): Easy to print, biodegradable, and great for beginners.

-

ABS (Acrylonitrile Butadiene Styrene): Strong and heat-resistant but requires a heated bed and enclosure.

-

PETG: A durable, flexible, and low-odor option suitable for functional parts.

-

Filled Filaments: Contain additives like carbon fiber or metal powder for added strength and aesthetics.

Choosing the right filament depends on mechanical needs, temperature resistance, and visual finish.

9. Print Bed

The print bed is the platform where the object is built layer by layer.

Most beds are made of aluminum or glass, and many include a heating element to improve layer adhesion and reduce warping. Removable build plates with textured surfaces can simplify part removal and reduce print damage.

Upgrading a bed may involve adding auto-leveling sensors, magnetic build plates, or thermal insulation for consistent heat distribution.

10. Feeder System

The feeder system delivers filament from the spool to the extruder. It ensures consistent feeding and tension, which are crucial for high-quality prints.

Advanced printers may include multi-color feeder systems that automatically switch between different filaments without dual extruders, streamlining complex print jobs.

How To Identify and Replace 3D Printer Parts

Many 3D printer components have identifiable serial numbers or markings. Manufacturers often provide spare part catalogs or exploded assembly diagrams on their websites. When replacing a part, consult the printer’s official manual or online guides to ensure correct installation and calibration.

Common Questions About 3D Printing Parts

Is assembling a 3D printer difficult?

Most consumer printers come semi-assembled, requiring only minor setup. DIY kits demand more technical skill but offer greater customization.

Where can I buy 3D printer parts?

Replacement and upgrade parts are widely available through online retailers or directly from printer manufacturers. KingsMG, for example, offers a full range of verified components compatible with leading printer brands.

How much do 3D printer parts cost?

Costs vary depending on component type and quality. Electronics such as controller boards are usually inexpensive, while high-end extruders and heated beds can be more costly.

Can I upgrade my 3D printer?

Yes. Common upgrades include silent stepper drivers, all-metal hot ends, larger build plates, or firmware updates for enhanced functionality.

Summary

This article reviewed the 10 essential 3D printer components and explained how each contributes to successful additive manufacturing. Understanding these systems helps users improve print quality, troubleshoot problems, and make informed upgrade decisions.

KingsMG provides a wide range of manufacturing solutions, including professional 3D printing services, precision machining, and custom part production. Whether you’re prototyping a new design or scaling up for production, KingsMG offers expert guidance and reliable manufacturing support.

Visit the KingsMG website to learn more or request a free, no-obligation quote for your next project.

Disclaimer:

The information in this article is for general educational purposes only. KingsMG makes no warranties regarding completeness or accuracy. Design specifications, tolerances, and materials should be independently verified before use. Always consult KingsMG or your printer manufacturer for project-specific requirements.