When choosing a filament for your next 3D printing project, PLA (Polylactic Acid) and PLA+ (enhanced PLA) are two of the most common options available. At first glance, they may seem nearly identical, but there are important distinctions between them that can significantly affect your final print.

While both materials share similar printing characteristics, three main factors set them apart — mechanical strength, printability, and cost. PLA is known for being affordable, easy to use, and ideal for beginners. PLA+, on the other hand, is a modified version of PLA, designed with additives that improve strength, toughness, and layer adhesion.

This article explores the detailed differences between PLA and PLA+, compares their advantages and disadvantages, and helps you decide which is better suited for your specific application.

What is PLA?

PLA is a biodegradable thermoplastic derived from renewable natural resources such as corn starch or sugarcane. Unlike petroleum-based plastics, PLA is considered an eco-friendly “bioplastic.” It was first synthesized in 1845 and has since become one of the most widely used materials in Fused Deposition Modeling (FDM) 3D printing.

Because it’s easy to print, requires relatively low extrusion temperatures, and doesn’t need a heated bed, PLA is the go-to choice for hobbyists, educators, and rapid prototyping applications.

Advantages of PLA

-

Affordable and accessible: PLA is one of the most inexpensive filaments on the market.

-

Environmentally friendly: Made from renewable sources and biodegradable under industrial composting conditions.

-

Easy to print: Requires low extrusion temperatures (190–220°C) and minimal printer calibration.

-

Excellent surface detail: Produces high-resolution prints with minimal warping or stringing.

Disadvantages of PLA

-

Low mechanical strength: PLA is brittle and not suitable for high-impact or load-bearing applications.

-

Limited heat resistance: PLA softens around 55–60°C, making it unsuitable for high-temperature environments.

-

Poor dimensional stability: Slow crystallization can lead to deformation under stress.

-

Moisture sensitivity: PLA absorbs humidity from the air, which can affect print quality.

Because of its simplicity and eco-friendly profile, PLA remains the preferred choice for decorative parts, prototypes, and non-functional models.

What is PLA+?

PLA+ is an enhanced version of standard PLA that includes additives or polymer modifiers to overcome PLA’s limitations. These additives are typically elastomers, impact modifiers, or proprietary blends that increase strength, flexibility, and heat resistance.

There is no single universal formula for PLA+, as each manufacturer designs its own version. However, most PLA+ filaments offer improved layer adhesion, smoother finishes, and better resistance to cracking.

Advantages of PLA+

-

Higher strength and toughness: PLA+ parts can handle more stress and impact than standard PLA.

-

Better thermal stability: Can resist heat up to 70–75°C, depending on the formulation.

-

Improved surface finish: Produces smoother, glossier prints with excellent layer bonding.

-

More durable components: Reduced brittleness makes it suitable for light functional parts.

Disadvantages of PLA+

-

Higher cost: PLA+ typically costs between $25–35 per kilogram, compared to $15–20 for standard PLA.

-

Slightly more difficult to print: Requires higher extrusion temperatures (around 210–230°C) and sometimes a heated bed.

-

Less eco-friendly: The additives used reduce biodegradability.

PLA+ offers the perfect balance between ease of use and enhanced performance, making it ideal for practical prototypes and light-duty functional parts.

PLA vs. PLA+: Key Differences

| Attribute | PLA | PLA+ |

|---|---|---|

| Ease of Printing | Very easy | Easy, but requires fine-tuning |

| Strength & Durability | Moderate, brittle | High, more flexible |

| Heat Resistance | ~55–60°C | ~70–75°C |

| Dimensional Accuracy | ±0.05 mm | ±0.03 mm |

| Surface Finish | Slightly rough | Smooth, glossy |

| Biodegradability | High | Moderate (due to additives) |

| Cost (per kg) | $15–20 | $25–35 |

| Best Use | Decorative parts, prototypes | Functional parts, moderate-stress applications |

From the table, it’s clear that PLA+ outperforms PLA in terms of strength, finish, and heat tolerance—but with a higher cost and slightly more demanding printing conditions.

Mechanical and Thermal Performance

PLA+ is specifically designed to address the weaknesses of PLA in mechanical strength and thermal stability. The inclusion of polymeric modifiers gives PLA+ higher tensile strength and ductility, meaning it can withstand bending and impact forces more effectively.

While standard PLA is prone to cracking or breaking under stress, PLA+ maintains structural integrity in light load-bearing applications, such as brackets, enclosures, or mechanical prototypes.

In terms of heat resistance, PLA+ holds up better in environments where temperatures reach 60–75°C, whereas standard PLA parts may deform around 55°C. However, both materials still fall short of PETG or ABS when it comes to true high-temperature performance.

Printability and Speed

PLA remains the easiest filament to print, making it the top choice for beginners. It adheres well to the print bed, produces minimal warping, and allows for fast print speeds (up to 100 mm/s).

PLA+, while still user-friendly, benefits from a bit more precision. It generally prints best between 40–80 mm/s, requiring careful calibration of temperature and cooling to achieve optimal results.

If you value speed and simplicity, standard PLA is the way to go. If you’re aiming for stronger, more detailed parts, PLA+ provides an upgrade worth the extra effort.

Surface Finish and Aesthetics

One of the standout advantages of PLA+ is its surface quality. The improved flow characteristics and layer adhesion produce prints with fewer visible layer lines and a smoother, more professional appearance straight off the printer.

PLA, in contrast, often has a slightly matte and textured surface. While this can be improved through sanding or polishing, PLA+ delivers a more refined finish right away—ideal for display models, prototypes, or consumer-facing parts.

Environmental Impact and Biodegradability

PLA is considered a bioplastic because it’s made from renewable agricultural sources. It’s compostable in industrial facilities, although it doesn’t degrade quickly in normal household conditions.

PLA+ retains some of this eco-friendly character but loses a degree of biodegradability due to the synthetic additives used to enhance its properties.

If environmental sustainability is a key factor for your project, standard PLA is still the more eco-conscious choice.

Applications: When to Use PLA vs. PLA+

Both PLA and PLA+ are widely used across hobbyist, educational, and industrial settings. However, their use cases differ depending on mechanical and thermal requirements.

PLA Applications

-

Concept models and prototypes

-

Educational projects and art pieces

-

Decorative items and low-stress assemblies

-

Lightweight consumer products

PLA+ Applications

-

Functional prototypes and light mechanical components

-

Small enclosures, brackets, and fixtures

-

Automotive interior parts (non-structural)

-

Consumer goods requiring improved aesthetics and durability

In short, PLA+ extends the usability of PLA, making it suitable for functional applications that demand moderate strength and stability.

Dimensional Accuracy and Print Quality

PLA+ generally exhibits better dimensional precision, with tolerances around ±0.03 mm compared to ±0.05 mm for PLA. This makes it a better choice for precision assemblies where tight fits are required.

Additionally, PLA+ parts tend to maintain shape more consistently during cooling, reducing shrinkage and improving layer alignment.

For high-precision models or multi-part assemblies, PLA+ offers the accuracy and stability that PLA sometimes lacks.

Toxicity and Safety

Both PLA and PLA+ are considered non-toxic and safe for general printing use. The additives in PLA+ are typically non-toxic elastomers such as TPU (thermoplastic polyurethane). However, neither material is certified as food-safe unless explicitly labeled by the manufacturer.

Always print in a well-ventilated environment, as all thermoplastics can emit mild fumes when heated.

Cost Comparison

Cost is one of the most significant differentiating factors between the two materials.

-

PLA: $15–20 per kg

-

PLA+: $25–35 per kg

For large-volume or educational printing projects, PLA offers the best cost-efficiency. For professional prototypes or functional applications, the additional cost of PLA+ is justified by its enhanced properties and improved finish quality.

Conclusion: Which Should You Choose?

Both PLA and PLA+ are excellent choices for 3D printing, but the right option depends on your project goals:

-

Choose PLA if you need low-cost, easy-to-print filament for visual models, prototypes, or educational projects.

-

Choose PLA+ if you need stronger, smoother, and more durable parts that can handle moderate heat and stress.

While PLA remains the gold standard for entry-level printing, PLA+ represents the next step toward functional and professional-grade results.

About KingsMG

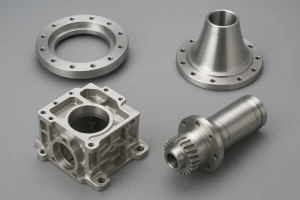

At KingsMG, we specialize in advanced 3D printing, CNC machining, injection molding, and sheet metal fabrication. Whether you need rapid prototyping or full-scale production, our team provides comprehensive manufacturing solutions with precision and speed.

Visit the KingsMG website today to explore our full range of materials and manufacturing services, or request a free, no-obligation quote to bring your ideas to life.

Disclaimer:

The content provided here is for informational purposes only. KingsMG makes no express or implied warranty regarding the accuracy or completeness of this information. Actual material performance may vary depending on equipment, design, and environmental factors. For specific design and manufacturing requirements, please refer to KingsMG’s official terms and conditions.