Introduction

The year 2025 marks a defining moment in global manufacturing. Across industries, from shipbuilding to aerospace, AI-powered collaborative robots and intelligent workholding systems are no longer experimental—they are operational realities.

Jigs and fixtures, once regarded as static tools for locating and holding parts, have transformed into dynamic, AI-integrated workholding devices capable of making decisions, predicting failures, and achieving ultra-precise tolerances of up to 0.00005 inches.

Valued at $25.8 billion in 2025, the global market for jigs and fixtures is forecast to climb to $42.1 billion by 2030. This growth is fueled by the Industry 4.0 tipping point, where smart factories become the rule rather than the exception.

This blog explores how next-generation jigs and fixtures are revolutionizing the production floor, enabling dark factories, reshaping machining through cognitive automation, and preparing manufacturers for the 2026–2030 technological horizon.

Understanding Jigs and Fixtures in the 2025 Manufacturing Landscape

Traditionally, jigs guided cutting tools while fixtures simply held parts in place. In 2025, the distinction remains, but the functionality has radically evolved.

-

Jigs today not only direct tools but also communicate directly with AI-driven systems, optimizing cutting conditions, predicting tool wear, and automatically compensating for material inconsistencies.

-

Fixtures now act as intelligent platforms—supporting, locating, and monitoring parts while feeding real-time data into manufacturing execution systems (MES). They anticipate clamp failures, adjust force dynamically, and enable seamless collaboration with robots.

For example, in next-generation drilling operations, sensor-embedded jigs detect slight variations in materials and instantly adjust cutting paths. Fixtures equipped with vibration monitoring forecast failures before they happen, ensuring uninterrupted production.

The essence of 2025 manufacturing transformation: jigs and fixtures are no longer passive tools—they are active manufacturing companions.

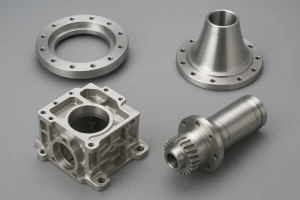

Precision Machining in the AI Era

Ultra-tight tolerances once achievable only in laboratory conditions are now routine on production floors, thanks to AI-enhanced jigs and fixtures.

Revolutionary Jigs and Fixtures Performance Matrix

| Smart Tool Type | 2025 Tolerance | AI-Enhanced Capability | Setup Time | Next-Gen Applications |

|---|---|---|---|---|

| AI-Guided Template Jigs | ±0.001″ to ±0.003″ | Auto-compensation | 30 sec | Adaptive sheet metal |

| Smart Plate Jigs | ±0.0005″ to ±0.002″ | Predictive positioning | 45 sec | CNC machining integration |

| Cognitive Box Jigs | ±0.0002″ to ±0.001″ | Real-time adjustment | 1–2 min | Multi-axis automation |

| Automation Fixtures | ±0.00005″ to ±0.0005″ | Dark factory ready | 15 sec | Lights-out production |

| Cobot-Integrated Fixtures | ±0.0001″ to ±0.0008″ | Human-robot collaboration | 20 sec | Flexible manufacturing |

2025 Material Intelligence Comparison

| Smart Material | Thermal Compensation | AI-Ready Sensors | Cost Factor | Applications |

|---|---|---|---|---|

| AI-Enhanced Tool Steel | ±0.00002″/°F | Integrated | 5x | Aerospace, dark factories |

| Smart Aluminum Alloys | ±0.0001″/°F | Embedded | 2x | Cobot integration |

| Composite Hybrids | ±0.00005″/°F | Built-in | 4x | Medical, precision machining |

| Nano-Enhanced Cast Iron | ±0.00003″/°F | Standard | 2.5x | Heavy-duty automation |

Automotive Manufacturing 2025: The Cobot Revolution

The automotive sector exemplifies the cobot-driven transformation. With 70% of leading OEMs using AR/VR for industrial operations, smart fixtures now collaborate with robots and operators alike.

Key Industry Performance Metrics

-

Setup time reduced by 80–90% via AI automation

-

First-part accuracy at 99.95% through cognitive adjustment systems

-

Cycle times improved by 45–60% with cobot integration

-

Uptime reaching 95% through predictive maintenance

Case Study: Tesla’s Austin Gigafactory deploys AI-powered welding fixtures that dynamically adjust clamping forces based on predicted thermal expansion. The result? 0.0002-inch repeatability across more than 4,000 daily assemblies.

Smart Workholding Integration in 2025

Modern fixtures are far more than steel and clamps. They integrate:

-

Edge-cloud processing for local decision-making paired with cloud-level analytics.

-

Collaborative interfaces to allow human-robot workflows without conflict.

-

Predictive algorithms that prevent 98% of fixture-related failures.

-

Real-time feedback loops enabling millisecond corrections.

Dark Factories: CNC Machining Reimagined

By 2025, the concept of dark factories—fully automated facilities without human presence—has become operational in multiple industries. Intelligent jigs and fixtures are the backbone of these systems.

Cognitive Automation Capabilities

-

Adaptive tolerances: ±0.00001″ to ±0.0001″

-

Autonomous fixture reconfiguration in under 2 minutes

-

Predictive quality control prevents defects before they occur

-

Continuous machine learning ensures processes self-optimize over time

Advanced Clamping Intelligence Matrix

| Material Category | AI-Calculated Force | Dynamic Adjustment | Distortion Prevention | Cobot Compatibility |

|---|---|---|---|---|

| Aerospace Titanium | 600–1200 psi | ±5% | AI-monitored | Full integration |

| EV Components | 300–700 psi | ±3% | Thermal compensation | Collaborative mode |

| Medical Implants | 100–400 psi | ±1% | Vibration nullified | Sterile operation |

| Consumer Electronics | 50–200 psi | ±2% | Micro-adjustment | Delicate handling |

Solving 2025 Manufacturing Challenges

Challenge 1: Workforce Transition

With experienced operators retiring, AI workholding devices capture and replicate expertise.

-

Knowledge capture through AI before experts retire

-

Visual/haptic setup guidance for new workers

-

Continuous learning that mirrors expert judgment

Challenge 2: Supply Chain Reshoring

Reshoring brings manufacturing closer to consumers, requiring adaptive precision.

-

Modular fixture platforms: reconfigured within minutes

-

Local customization without redesign

-

AI-assisted knowledge transfer to regional plants

ROI Revolution in Smart Fixtures

The economics of investing in smart jigs and fixtures in 2025 are compelling.

Next-Gen ROI Formula

ROI = AI Gains + Cobot Integration + Dark Factory Readiness

Example Calculation:

-

AI setup reduction: $37,500 annual savings

-

Predictive maintenance: $190,000 daily uptime value

-

Quality improvements: $3,000 defect reduction

-

Cobot throughput: $20,000 productivity gain

-

Total Value: $250,500 annually per deployment

Implementation Phases:

-

Months 3–6: Smart fixture deployment with edge computing

-

Months 7–8: Cobot integration and operator training

-

Months 9–12: Dark factory preparation and cognitive automation

Quality 4.0: Real-Time Monitoring

| Smart Component | Monitoring Frequency | AI Analysis | Predictive Action | Integration Level |

|---|---|---|---|---|

| Clamping Force | 1000Hz | Optimization | Auto-adjustment | Full AI control |

| Thermal Compensation | 100Hz | Expansion prediction | Micro-positioning | Collaborative |

| Vibration Sensors | 500Hz | Pattern recognition | Damping activation | Autonomous |

| Wear Detection | Continuous | Life prediction | Scheduled replacement | Predictive |

2025–2030 Technology Horizon

The next five years will accelerate breakthroughs:

-

Quantum sensing for sub-micron precision (±0.000001-inch).

-

Bio-inspired clamping with adaptive material intelligence.

-

AR holographic setup for real-time training overlays.

-

Neural-network optimization of clamping strategies.

-

Sustainable fixtures with energy monitoring and carbon tracking.

Industry 5.0 Outlook: Human-AI collaboration, mass customization, and resilient, distributed supply chains will define the era.

Conclusion

Jigs and fixtures have evolved from static supports into intelligent manufacturing partners. The 2025–2030 era promises not just smarter tools, but predictive, autonomous, and even self-healing systems.

Manufacturers embracing AI-powered workholding devices today are positioning themselves as leaders of tomorrow’s competitive landscape. From quantum-level tolerances to sustainable Industry 5.0 practices, the journey begins with fixture innovation in 2025.

KingsMG: Your Partner in Smart Manufacturing

At KingsMG, we specialize in helping manufacturers embrace this transformation with:

-

Custom AI-enabled fixture design with quantum-ready architecture

-

Dark factory preparation and consulting

-

Collaborative robot integration for optimal workflows

-

Predictive maintenance systems ensuring 95%+ uptime

With KingsMG’s expertise in AI-powered jigs and fixtures, you gain a clear competitive advantage—today and in the years to come.

FAQs

Q: How do AI-powered jigs and fixtures differ from traditional ones?

A: Unlike static fixtures, smart devices self-calibrate, adjust clamping forces, and integrate with robots. They also predict failures, achieving 95% uptime.

Q: What tolerance levels are possible?

A: Standard smart fixtures achieve ±0.0005″, while advanced aerospace systems already reach ±0.00005″. Prototypes using quantum sensing aim for ±0.000001″ by 2030.

Q: How do I prepare for dark factory adoption?

A: Start with IoT-ready fixtures, edge-cloud data processing, and cobot integration. With proper planning, many factories achieve partial dark factory operation in under a year.

Q: Can old fixtures be upgraded?

A: Yes. Retrofit kits costing 30–40% of new systems deliver up to 80% of smart functionality, extending fixture life cycles.

Q: Will smart manufacturing replace human jobs?

A: No—it transforms them. Operators shift from repetitive tasks to higher-value roles in optimization, AI collaboration, and data analysis. Productivity rises by 25–30% without reducing workforce size.