Day 2, 3:07 p.m. A carton leaves the dock with finished, inspected parts.

Day 1, 11:40 p.m. A pallet pool swaps fixtures while robots tend machines through the night.

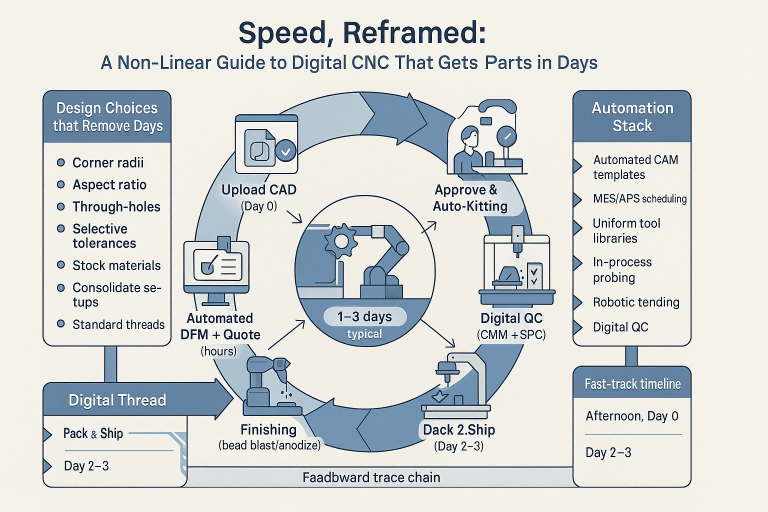

Day 0, 4:12 p.m. You approve an online quote that already highlights risky features and shows the trade-off between price and lead time.

T-minus 6 hours. Your CAD file hit a system that analyzed geometry, selected tools, generated templated toolpaths, planned inspection, and scheduled machines before anyone checked email.

If that timeline feels upside-down, good—that’s how a digital CNC model beats the clock: by front-loading intelligence, standardizing execution, and letting software orchestrate the boring bits.

Below is a deliberately shuffled field guide to the same destination—parts in hand, fast—so you can grab the ideas you need in any order.

1) Start at the End: What “Fast” Actually Looks Like

-

Predictable lead times instead of “we’ll see next week.”

-

Right-first-time parts because the manufacturability issues were resolved before programming.

-

Elastic capacity that absorbs spikes or urgent repeats.

-

Data you can trust—from versioned CAM to inspection results—so reorders don’t relitigate the past.

Speed is not only ship dates; it’s shorter learning cycles that pull your next revision forward.

2) Five Green Flags When Choosing a Digital CNC Partner

-

Volume agility, not a single trick. They can run a one-off, a bridge build, and a short production order without reinventing the workflow each time.

-

Standardized everything. Shared tool libraries, fixtures, setup sheets, and material SKUs. If every job is “special,” every job will be slow.

-

Automated DFM with transparent trade-offs. Quotes that update as you tweak materials, quantities, tolerances, or finishes—in hours, not days.

-

Connected quality. In-machine probing, digital FAI, and SPC routed back into the same system that scheduled the job.

-

Process breadth + honest guidance. They suggest CNC when it’s faster than 3D printing for your geometry—and the reverse when it’s not.

3) Design Choices That Remove Days (Without Killing Your Design)

Think of these as time multipliers:

-

Corner radii that match cutter radius. If a 3 mm end mill must clear a pocket, spec ≥ 3 mm internal radii to avoid babysitting micro-tools.

-

Depth discipline. Keep slot and pocket depths ≤ 4–6× tool diameter for standard tooling and stable cuts.

-

Through-features beat blind ones. Through-holes aid chip evacuation and faster inspection.

-

Selective tolerances. Apply tight callouts where function demands; leave the rest at practical shop defaults.

-

Use stocked alloys and finishes. 6061-T6, 7075-T6, 304/316, 1018/4140, bead-blast, anodize, passivation—these move.

-

Consolidate reachable faces. Aim for two or three work orientations; every extra setup is a day waiting to happen.

-

Standard threads and depths. Coarse/regular series, standard engagement. Specialty taps and thread mills slow everything.

4) Under the Hood: What Actually Makes It Fast

Here’s the (unordered) stack most “fast shops” quietly rely on:

-

Automated CAM templates. Feature recognition + parameterized toolpaths for pockets, contours, drilling, tapping.

-

Uniform tool libraries. Pre-vetted cutters/holders with known limits reduce guesswork and warm-up runs.

-

Robotic tending & pallet systems. Setups happen offline while spindles keep cutting—hello, lights-out.

-

In-process probing. Touch probes set work offsets, check features mid-cycle, and compensate for wear.

-

MES/APS orchestration. A Manufacturing Execution System and planning engine route jobs based on live capacity, due dates, materials, and skills.

-

Closed-loop QC. CMM/vision data feeds SPC; trends adjust toolpaths or flags before scrap accumulates.

This isn’t about a single hero machine; it’s software-coordinated consistency across many small wins.

5) The Digital Thread (Explained Backwards)

Shipment labels and inspection reports make sense because every upstream decision is versioned:

inspection plans trace to toolpaths → toolpaths trace to setups → setups trace to DFM results → DFM results trace to your uploaded CAD. That single source of truth lets a shop repeat success on another machine, in another cell, or even at a partner site—without phone tag.

Outcomes of that thread:

-

Traceability without drama.

-

Repeatability on demand.

-

Lead times you can schedule around.

6) The Quote Is the Product (Before the Product Exists)

A quick, interactive quote is more than a number; it’s risk surfaced early:

-

Thin walls, tool access, deep pockets, tiny fillets, thread spec mismatches—flagged at upload.

-

Pricing sliders show the cost/time impact of quantity, material, finish, or tolerance changes.

-

You revise from your desk once instead of discovering a showstopper after programming.

This is why a “quote in hours” isn’t a gimmick; it’s the first compression of your timeline.

7) Supply Chain Reality Check: Speed That Survives Stress

Digital CNC should also lower your operational risk:

-

Elastic capacity absorbs urgent orders—software routes them intelligently.

-

Consistent lead times emerge from data, not optimism.

-

Standardization reduces variability so OTD and budget stop fighting each other.

Result: you can move faster and sleep better.

8) A Timeline You Can Steal (But Read Out of Order)

-

Afternoon, Day 0 — Approve the quote; PO flips the job to auto-kitting: stock pulled, fixtures assigned, templates selected.

-

Evening, Day 0 — Setup with standardized workholding; probing sets offsets; first article hits digital inspection.

-

Overnight, Day 1 — Palletized batches run lights-out; any drift triggers pauses before scrap piles up.

-

Day 2–3 — Deburr/finish (bead-blast, anodize, passivation), final inspection, pack, ship.

Not every part fits this arc, but for many geometries, 1–3 days is the new normal when the digital thread does the heavy lifting.

9) Practical Moves That Keep You on the Fast Track

-

Freeze the rev. Changes after programming are timeline kryptonite.

-

Let the model rule. Only attach a drawing for critical GD&T; don’t duplicate what the CAD already says.

-

Bundle variants. Share setups across A/B concepts to compress total time.

-

Agree on acceptance criteria early. Define tolerances, finishes, and inspection levels up front.

-

Pick fast finishes. Standard finishes save entire days.

-

Stage reorders. With a digital thread, repeat runs should skip discovery—use them.

10) Why Speed Compounds: Learning Loops

Short lead times create shorter learning cycles:

-

Each DFM round teaches your team which features slow machining.

-

SPC reveals which tolerances are habitually over-specified.

-

Toolpath templates evolve as your parts recur.

Across a few iterations, parts become naturally machinable; quotes drop, and schedules tighten—without heroics.

11) FAQ (Jumbled, Because Real Life Is)

Q: Can a digital shop really handle both one-offs and short-run production?

A: Yes—when fixtures, tools, and CAM templates are standardized, the marginal cost of switching scales down as easily as up.

Q: Isn’t robotic tending overkill for prototypes?

A: Robots don’t just tend; they stabilize schedules by removing human timing variability. Even prototypes benefit from that predictability.

Q: Will tight tolerances kill my lead time?

A: Only when they’re everywhere. Put microns where function demands; leave the rest practical.

Q: Do I need to change my CAD workflow?

A: Not radically. Upload native CAD or STEP; keep drawings to true GD&T. The less retyping, the faster the flow.

Q: How do I know the shop isn’t over-promising?

A: Ask to see their planning logic: queue depth, machine utilization, and standard lead-time bands by material/finish. Data beats adjectives.

12) The Out-of-Order Summary (So You Can Act Today)

-

Pick a partner with standardized tools/fixtures, automated DFM, connected QC, and real scheduling data.

-

Design for time: sensible radii, depths, materials, tolerances, thread choices, and reachable faces.

-

Use the quote to make trade-offs right now—don’t wait to discover problems after programming.

-

Let the system run: pallet pools, probing, MES, and SPC turn “fast once” into fast reliably.

-

Iterate quickly: treat every job as a lesson; your parts (and lead times) will get better with each loop.

Final Word

Speed used to mean begging for favors and living with surprises. In a digital CNC model, it means front-loaded certainty, software-driven consistency, and learning that compounds. Whether you read this guide top to bottom or dipped in randomly, the throughline is simple: standardize what repeats, automate what bores, and decide early with data. Do that, and “parts this week” becomes an expectation—not an exception.