The global supply chain continues to experience unprecedented challenges. Rapidly evolving tariff landscapes are predicted to create a domino effect across industries, raising questions about consumer willingness to pay higher prices in uncertain times.

Over the past five years, supply chains have been severely tested—by the COVID-19 pandemic, the Suez Canal blockage, and geopolitical conflicts such as the Russia-Ukraine war. Each crisis disrupted trade flows but also generated valuable lessons that companies have used to strengthen resilience.

Fortunately, the technological evolution of manufacturing has made supply chain agility more achievable than ever. A diversified supplier base combined with digital manufacturing capabilities allows businesses to maintain stability and speed, even in turbulent environments.

Digital Manufacturing Enables Supply Chain Resilience

Kingsmg works with a wide range of global enterprises, witnessing firsthand the industry shift toward “manufacturing closer to consumption.” Since the emergence of COVID-19, many of our customers have highlighted the importance of supplier speed and flexibility as vital components of continuity and responsiveness.

Manufacturers that combine agility, speed, and uncompromising quality will be key to achieving resilience in modern supply chains.

Kingsmg addresses this challenge through a dual-structured supply chain model: leveraging our self-owned production facilities and an actively managed network of global manufacturing partners.

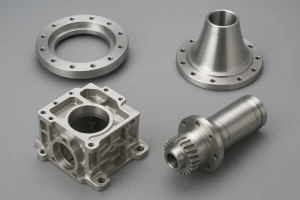

- In-house Manufacturing Capabilities: Kingsmg’s factories specialize in injection molding, CNC machining, 3D printing, and sheet metal fabrication. We deliver industry-leading speed and quality for prototypes as well as production runs.

- Global Partner Network: Our highly vetted manufacturing partners expand production capacity and technical capabilities, ensuring we can meet diverse customer needs while maintaining strict quality compliance.

The Advantage of CNC Machining and Non-Standard Parts

In today’s complex trade environment, CNC machining and non-standard/custom parts play a critical role in enhancing supply chain resilience:

- Rapid Response to Market Needs

CNC machining enables the fast production of complex components, essential for prototyping, small-batch validation, or urgent spare parts. Unlike traditional tooling, CNC offers unmatched flexibility, significantly reducing development lead time. - Adaptability for High-Mix, Low-Volume Production

Non-standard parts are often required in small, customized quantities. Kingsmg can quickly process custom parts based on customer drawings, eliminating the limitations of standard molds and large minimum order quantities. This reduces inventory pressure and optimizes working capital. - Precision and Reliability

CNC machining delivers the high accuracy demanded by industries such as aerospace, automotive, medical, and energy. For high-value markets, supply chain precision and consistency are directly linked to competitiveness. - Elastic Supply Chain for Non-Standard Demands

Non-standard parts often involve irregular specifications and tight delivery schedules. Kingsmg integrates custom part production into a standardized digital workflow, supported by intelligent scheduling and supply chain visibility, ensuring reliable and fast delivery.

This flexibility allows our customers to adapt quickly to tariff changes or logistics delays, maintaining continuity in production.

A Comprehensive Digital Manufacturing Model

Kingsmg’s digital manufacturing model is designed to help clients weather tariff fluctuations while enhancing long-term agility.

- Dual Assurance System: The combination of in-house facilities and our global partner network delivers fast, scalable, and flexible production solutions.

- Proactive Raw Material Sourcing: Our domestic factories employ forward-looking material procurement strategies, enabling swift responses to geopolitical disruptions and reducing the impact of price volatility.

- Supplier Diversification: A geographically diverse supplier base minimizes risks associated with regional tariffs, regulatory changes, or transport disruptions, ensuring reliable delivery worldwide.

With this model, Kingsmg supports the full product lifecycle—from prototyping to pilot runs, and from low-volume to large-scale production—helping clients reduce risk while improving operational efficiency.

Flexible Orders and Smarter Inventory

Kingsmg supports no minimum order quantities, giving customers the flexibility to order exactly what they need. This reduces inventory costs and helps streamline cash flow.

We understand that speed and flexibility are critical to agility. Alongside rapid turnaround times, we enforce rigorous quality control measures and complete documentation at every stage of the process. Every component we deliver meets the highest international standards.

End-to-End Service and Compliance

Kingsmg is more than a manufacturer—we are your full-service supply chain partner. We provide:

- Customs and tariff classification guidance;

- Delivered duty-paid (landed cost) quotations at checkout, inclusive of duties, VAT, fees, and tariffs;

- Proactive policy monitoring to ensure compliant, transparent delivery processes.

This one-stop service helps customers lower risks and achieve cost efficiency in uncertain trade environments.

Conclusion

The complexity and volatility of global supply chains will persist. However, companies that embrace digital manufacturing, CNC machining, and flexible non-standard part supply chains will be best positioned to maintain resilience and competitiveness.

At Kingsmg, we remain committed to delivering speed, flexibility, strict quality, and comprehensive service, ensuring our customers’ supply chains remain robust and responsive to global challenges.

We look forward to being your trusted long-term partner, helping you navigate tariffs, safeguard production, and succeed in a highly competitive international market.